General Information

| Completion: | 10 August 2013 |

|---|---|

| Status: | in use |

Project Type

| Structure: |

Rigid frame bridge with V-shaped legs |

|---|---|

| Function / usage: |

Road bridge |

| Material: |

Steel bridge Structurae Plus/Pro - Subscribe Now! |

Awards and Distinctions

| 2015 |

entry

for registered users |

|---|

Location

| Location: |

Hamburg-HafenCity, Hamburg, Germany |

|---|---|

| Part of: | |

| Coordinates: | 53° 32' 21.50" N 10° 0' 28.73" E |

Technical Information

Dimensions

| total length | 166.11 m | |

| span lengths | 44.06 m - 77.99 m (= 19.80 m + 38.39 m + 19.80 m) - 44.05 m | |

| length of movable section | 38.39 m |

Quantities

| structural steel | 2 150 t |

Cost

| cost of construction | ca. Euro 19 000 000 |

Materials

| deck |

steel

|

|---|---|

| piers |

steel

|

| foundations |

reinforced concrete

|

| abutments |

reinforced concrete

|

Case Studies and Applied Products

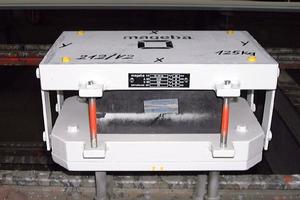

LASTO®BLOCK – Elastomeric Bearings

mageba elastomeric bearings, which conform to various international standards, such as the EN1337, DIN4141, BS5400 and AASHTO, are used globally for bridges and other engineering constructions.

[more]

RESTON®SPHERICAL – Spherical bearings

mageba spherical Bearings are especially suited for bridges with big torsions and bridges located in very cold areas (temperatures lower than -30°C).

[more]Baakenhafen Bridge, Hamburg

Client's Task

In an interdisciplinary bridge competition, HafenCity Hamburg GmbH set high technical and design goals for the new Baakenhafen Bridge. The structure was to set new standards in terms of use and sustainability. The task was to design an inner-city waterway bridge that combines these complex requirements with innovative solutions. The use of the Baakenhafen Bridge is characterized by the fact that in addition to two, later optionally three lanes, the popular Elbe cycle path will also run here in the future. The numerous events in HafenCity also mean that a high frequency of pedestrians can be expected. It was also important to find a good solution for crossing under the bridge.

Because riverside promenades run along both sides of Baakenhafen harbor, they play a special role in HafenCity as public exercise and leisure areas. Around 10km of promenades can be walked without having to cross a road, and Baakenhafen Bridge was to be no exception. Another task was to maintain access to the harbor basin even for larger ships and to ensure flexible usability of the water areas. To this end, a 30-meter-wide element was provided in the bridge's structure that can be lifted out if necessary to allow a larger ship, such as a museum ship, a fixed berth in Baakenhafen. A new sustainability assessment system developed jointly with Darmstadt Technical University has already been integrated into the competition and was an important component of the planning and realization phase. The target grade „good“ was to be achieved as a minimum.

Description of the main structure

The design by Wilkinson Eyre Architects and BuroHappold Engineering impresses with an approach that is both pragmatic and elegant, incorporating the local conditions and allowing the structure's lines of force flow to be experienced in a curved form. The basic idea is a skewed, semi-integral steel bridge structure consisting of three sections. The end spans cantilever over the center piers, which are resolved into two double-V columns, and support the excavated portion of the center span (Gerber articulated girder). The double-V-columns form two framed supporting structures due to the bearingless connections with the main girders. On the abutments, the outer segments rest on two horizontally sliding elastomeric bearings. The excavation section is supported on the cantilevers and rests on spherical bearings. The steel superstructure consists of two airtight welded box girders each. The main girders are connected to open, haunched cross girders that support the orthotropic roadway deck and sidewalks. The overall appearance develops an aesthetically curved structure that harmonizes well in its elegant proportions.

Choice of building materials

The double-V columns and the bridge superstructure made of steel with a total weight of approximately 2,500 tons were manufactured in only eight months. This was done almost entirely in the factory, protected from the weather, so that a special quality could be achieved. After assembly of the current piers, the superstructures were delivered in three complete sections on pontoons by sea from Belgium via the North Sea and assembled in just three days. The superstructure and substructure form a very aesthetically pleasing unit and require no maintenance. The elegant steel superstructure is supported by a robust substructure. The double-V columns tie into two piers comprising around 500m³ of concrete, which transfer their loads into the subsoil via 35m-long large-bore piles.

For a bridge designed to withstand high traffic loads, each element must meet the requirements for robustness, functionality and quality. However, the Baakenhafen Bridge also has special aesthetic and atmospheric qualities. Particular attention was paid to the elements that invite pedestrians to linger. The elegant stainless steel parapet exemplifies the high quality of the design. It accentuates the undulating motion of the entire bridge. Like the sculptural parapet, the wooden benches and seating steps are also carefully integrated into the overall form of the Baakenhafen Bridge.

Explanation of the design

The Baakenhafen Bridge allows speedy crossing of cars and cyclists, combined with a great view and a quality of stay „on the water“ especially for pedestrians. The gently flowing form spans Baakenhafen with an elegant gesture.

The pedestrian walkways form extensions on both sides of the bridge and follow the undulating static force flow lines along the entire length of the bridge. In cross-section, they are arranged so that their heights mirror each other: A high-level surface on one side corresponds with a low-level surface on the other. This creates exciting spatial experiences with sublime views extending from the cruise terminal to the west across the Norderelbe to the opposite bank of the Elbe, and intense proximity to the water. These deliberately decelerated belvederes convey a sheltered quality of stay through the raised main beams, inviting visitors to linger.

Special engineering achievement

Under the bridge, the typical Hamburg harbor launches can enter the former harbor basin unimpeded. To ensure that the bridge does not become a barrier and that large museum ships can also moor here, there is the lift-out element: in this process, a pontoon lifts out the middle segment of the cantilever beam structure with the force of the tide.

There has been no objective, standardized assessment of the sustainability of engineering structures in Germany to date. As one of five pilot projects, the Baakenhafen Bridge has contributed to the development of a new evaluation system. In this context, it is the first bridge nationwide for which the sustainability assessment system was already integrated into the competition and was an important component of the planning and realization phase.

What positive effects does the special engineering achievement have?

Down to the details, the high standards set by HafenCity Hamburg GmbH have opened up new avenues and promoted the usage and sustainability qualities of Baakenhafenbrücke in exemplary fashion. Particularly with regard to the requirements of sustainability, innovative and practical solutions have been produced. For example, when the V-shaped supports are connected to the superstructure, there are no maintenance-intensive bearings „above the water“ and no one has to „go under the bridge“ for maintenance of all the lighting. All maintenance is done from the bridge deck. The simple idea of inclining the lower crossbeam flanges to less than 45 degrees is an effective protection against fouling by birds. The drainage system integrated into the flanges avoids the structure being penetrated by drainage pipes. The fact that the center section of the bridge can be excavated with the force of the tide represents an entirely new step for the realization of a ship passage, saving costs and utilizing natural resources.

As the rating system showed, the sustainability quality of the Baakenhafen Bridge was not only maintained but even improved from competition to completion. It even achieved the rating „very good“. The positive experience gained from sustainability certification in the Baakenhafenbrücke project will help to decisively improve the quality of engineering structures over their entire life cycle.

Explanatory report by Wilkinson Eyre Architects / Happold Ingenieurbüro GmbH for submission to the Ulrich Finsterwalder Ingenieurbaupreis 2015

Participants

-

Wilkinson Eyre

- James Eyre (architect)

Relevant Web Sites

Relevant Publications

- (2014): Die Baakenhafenbrücke - innovative Nutzungsvielfalt und Nachhaltigkeit. In: Bautechnik, v. 91, n. 2 (February 2014), pp. 123-133.

- (2014): Nutzungsvielfalt und Nachhaltigkeit - Die Baakenhafenbrückein der HafenCity Hamburg. In: (2014): Ingenieurbaukunst 2015. Ernst & Sohn, Berlin (Germany), ISBN 9783433030967, pp. 26-35.

- About this

data sheet - Structure-ID

20065639 - Published on:

10/08/2013 - Last updated on:

18/01/2020