TENSA®GRIP RS & RS-LS – Single gap joints

The RS Expansion Joint is designed for highly loaded bridges with heavy traffic. In normal situations it allows movements up to 80 mm. The Single Gap Joint RS type construction consists of two heavy steel edge profiles with anchor brackets and a replaceable elastomeric sealing element.

Media

Principle

The mageba single gap expansion joint TENSA®GRIP Type RS consists of two heavy steel profiles (S235-JRG2) with anchor loops and a replaceable 5-point sealing element which ensures 100% water-tightness.The standard TENSA®GRIP Type RS joint allows for a total movement of up to 80mm. For special structures a movement range of up to 200 mm is possible. This can be achieved using a special sealing profile.

The TENSA®GRIP Type RS joint is designed for bridges with heavy traffic. Therefore, snowploughs or crawlers can travel over the joint without causing any damage.

Characteristics

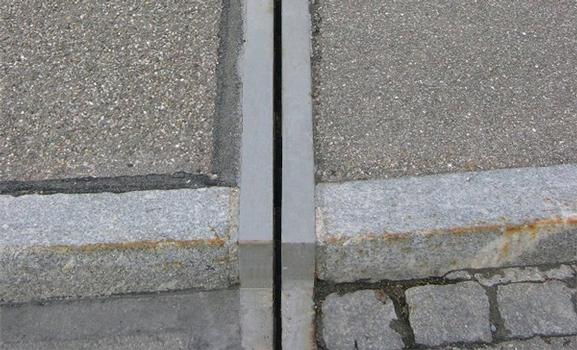

Asphalt carriageway, TENSA®GRIP Type RS-A

- Joint features connections to waterproofing membrane of the bridge and is fixed with anchor loops.

- Suitable for road surface thicknesses of 70mm to 250mm. Weight approx. 70 kg/m.

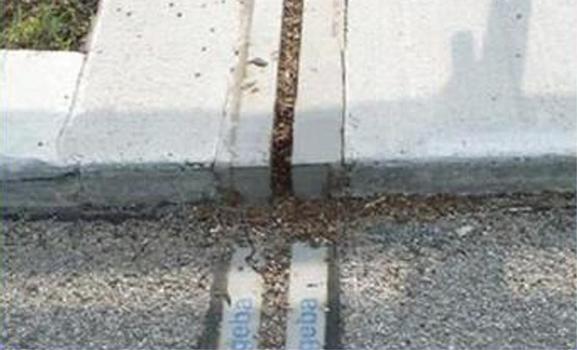

Concrete carriageway, TENSA®GRIP Type RS-B

- Joint features no connection for waterproofing membrane of the bridge and is anchored by horizontal shear studs. Weight approx. 40 kg/m.

Special equipment TENSA®GRIP Type RS-LS

- Joint with noise-reducing surface for longitudinal movements of up to 100 mm.

Rubber hump seal: optional and optimal

mageba developed and patented the so-called hump seal. It consists of an elastomeric sealing element with an asymmetric hump on the top. Due to this special shape, the hump maintains its height as the joint opens and closes.The hump profile keeps the joint gap free of dirt, especially of stones or other larger objects.

At the same time, the profile acts as a double-sealing band that keeps the joint watertight. In addition, it protects pedestrians with high heels from being caught in the joint gap.

Noise-reducing surface

Particularly in urban areas, expansion joints should not generate noise if this can be avoided. Therefore, mageba has developed its expansion joints to feature an optional noise-reducing surface.The unique patented "sinus plates” with their "teeth” design eliminate straight edges perpendicular to the direction of travel and ensure that vehicles travelling over the joint continuously grip the surface. In this way, noise generated by vehicles travelling over the joint is demonstrably reduced.

In contrast to finger joints, there is no restriction on the type of traffic passing over expansion joints with sinus plates. The special design of these sinus plates also permits cyclists to pass over the joint safely.

Expansion joints with sinus plates, called TENSA®GRIP SILENT, are very suitable for use on bridge structures in residential areas and in other areas that are sensitive to noise.

Noise measurements performed on different structures by an independent institute have shown that expansion joints with sinus plates are significantly less noisy (up to 70% less noise generated) than other types of expansion joint.

Detailed documentation on noise measurements is available upon request.

At footpaths: well adapted, well anchored

In footpath areas, the TENSA®GRIP Type RS joint adapts without any problems to the bridge geometry. It is connected with an anchor loop or, where there is a lack of space, by shear studs.Watertight and easily-replaced rubber seal

The TENSA®GRIP Type RS Joint is 100% watertight and its rubber seal can be easily replaced:- Sealing profile deliverable in EPDM or CR material

- A 5-point sealing system in the clamp area ensures 100% watertightness

- Screwless connection for easy and quick replacement – even after many years of operation

Assembly

The joints are assembled in the factory and delivered in a fixed condition according to the specified pre-setting value.On site, experienced technicians position the joints precisely and connect the anchoring to the bridge’s reinforcement. Then the joint’s temporary fixings are removed to allow the joint to open and close with the bridge movements, and the recesses are filled with concrete.

TENSA®GRIP joints can also be installed in stages as necessary. In this case the joints are delivered in sections which then are connected together.

Corrosion protection

The following standard corrosion protection is normally provided:- Sandblasting SA 3

- Zinc metal spray galvanizing, 50µm

- Two 40µm layers of top coat

Quality for good reasons

Many thousands of TENSA®GRIP Type RS joints, used under heavy traffic conditions for over 40 years worldwide, give proof of quality and durability. This is due to:- Qualified staff with many years of experience

- High-quality materials

- Modern Quality Assurance System (ISO 9001:2000 and EN 729-2)

- Professional installation of joints on the bridge

mageba group

mageba group