TENSA®FLEX RC – Sliding Finger joints

The Tensa®Flex slip finger can assimilate both horizontal and vertical movements and torsions. Modular structure makes possible the replacement of the system with minimum traffic interferences.

Media

Principle

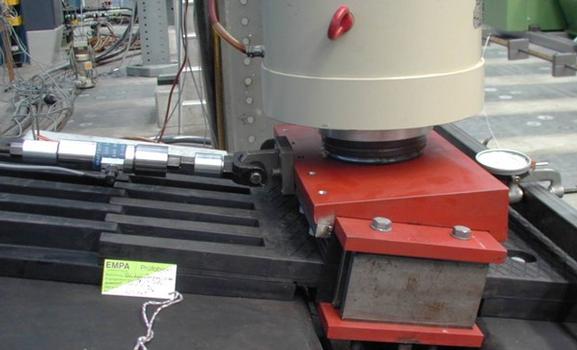

The TENSA®FLEX sliding finger expansion joint is a flexible metal-elastomeric bonded system which consists of two asymmetric parts. The cantilever fingers of the upper part are installed with a downward pre-tension and therefore apply a permanent pressure to the opposing sliding surface of the lower part. This allows horizontal movements of the bridge to be facilitated. The flexible arrangement of the system also reduces the effect of loading (especially heavy traffic) on the bridge structure.

Features

- High driving comfort and low noise emission.

- A simple system, without any moving parts.

- Due to ist shock-absorbing characteristics, the impact on the bridge from traffic is reduced considerably.

- Anchoring tried and tested for many years as a sealed connection.

- Easy and quick replacement of finger plates (within a matter of hours) thanks to modular design and simple anchoring from above.

- Can accommodate movements of up to 800mm.

- Jointed arrangement also allows rotational (fy, fz) and vertical movements (ez).

- Resistant against environmental impacts such as ozone, oils, fuels, de-icing salt and temperature.

Design

The TENSA®FLEX sliding finger consists of two steel parts, each of which has fingers that are vulcanised in elastomeric material. The cantilevered upper part of the joint (male) is pre-tensioned and thus always remains in contact with ist counterpart (female). These plates are both secure and elastic, thanks to the flexibly-arranged anchors. For movements of up to 200mm, the system can be installed in such a way that the gap is always covered, keeping the drainage channel free of debris. The expansion joint system is anchored onto a specially prepared concrete subsurface, and is therefore easily replaceable.Product idea

The TENSA®FLEX sliding finger joint was developed to reduce the impact of traffic loading on the main bridge structure and to be easily installed and replaced as necessary. It was also developed to minimise the noise generated by traffic travelling over the joint. Ist flexible and pre-tensioned arrangement also accommodates vertical movements (eg. Settlement) of the bridge while ensuring that the fingers will never protrude into the carriageway.This development, incorporating the flexibility of the elastomeric material in combination with the durability and simplicity of a steel finger joint, and the modular design (which facilitates easy replacement of parts), has resulted in the TENSA®FLEX sliding finger joint.

Pretensioned system

The cantilevered elements (male) of the upper part of the TENSA®FLEX sliding finger joint are vulcanised with a slight downwards inclination. In this way a pre-tension is created when the upper part is mounted on the lower (female) part of the joint.Jointed design

Unlike standard finger joint structures, the TENSA®FLEX sliding finger joint, thanks to ist elastomeric characteristics, is a pre-tensioned and jointed arrangement.This means that the cantilevering fingers of the joint, which are kept in constant contact with the lower part of the joint by the pre-tension, will not protrude above the carriageway surface. Furthermore, vertical structure movements (eg. Abutment settling or torsion) can be accommodated. Thus the mageba TENSA®FLEX sliding finger joint does not constitute a hazard, even to snow-clearing vehicles.

Optimal watertightness

The joint is sealed with a 5mm EPDM drainage channel. It is bolted and bonded to a fastening angle. Then a 1.4mm sealing foil is applied to the whole joint area and secured with a special adhesive.Additionally, both parts of the expansion joint apply pressure to the edges of the drainage channel, ensuring that the EPDM material stays in position and guaranteeing the watertightness of the joint. In order to enable routine maintenance works, the structure can also be equipped with a cover plate with cleaning flap.

Minimal noise generation

As there are no impacting or mechanically moving parts, the system is very quiet under traffic. Comparative measurements carried out during the bridge renovation of the Seez viaduct on the A3 motorway at Walenstadt (St Gallen, Switzerland) showed that the noise level was reduced by up to 18dBA through the installation of TENSA®FLEX sliding finger joint. Note: A noise level reduction of 10dBA is perceived by the human ear as being half as noticeable.References

Relevant Websites

- About this

data sheet - Product-ID

18 - Published on:

02/07/2007 - Last updated on:

17/11/2021

mageba group

mageba group