RESTON®SDD – Spring Disc Dampers

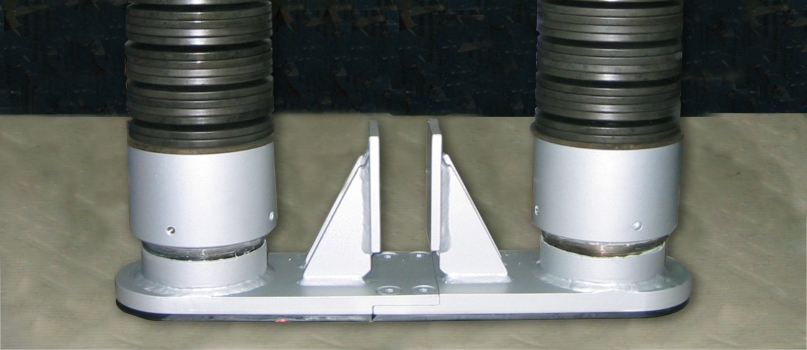

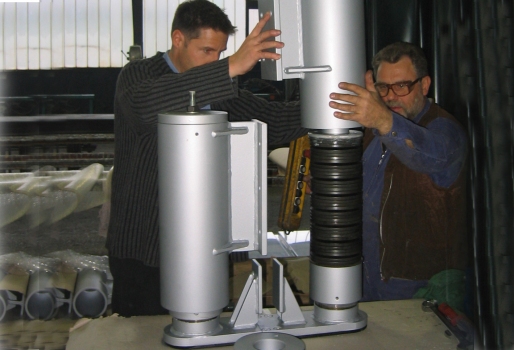

mageba RESTON®SDD Spring Disc Dampers consist of a steel tube containing a piston and a stack of disc springs. The disc springs deform under pressure from the piston, damping its movement. The system offers excellent reliability and durability.

Description

mageba RESTON®SDD spring disc dampers consists primarily of pillars/packets of disc springs, featuring high load capacity, highquality materials and excellent durability. RESTON®SDD spring disc dampers are typically used in structures which require dynamic compressive loads to be transmitted and damped. The product requires little installation space. The devices fulfil two main functions:

- Damping of introduced forces (linear, regressive or progressive)

- Ensuring a pre-defined maximum spring stroke for all load impacts

Applications

The range of possible applications of RESTON®SDD spring disc dampers is extensive.

The devices are widely used in bridge and general civil engineering structures, e.g. to stabilise the hanger cables of tied arch bridges. They are also widely used for industrial applications, such as automotive technology and chair lift systems. In building construction, RESTON®SDD are mainly installed in specialised structures that need permanently defined spring strokes such as façade construction, pre-stressing of cable structures and the like.

Design

A typical spring disc damper consists of disc-shaped, curved spring elements, which are assembled to form a pillar. Depending on the arrangement of the spring elements, the absorption force and the spring stroke can be adjusted. When installing spring disc dampers, the spring elements are normally pre-stressed. The installation length is determined by the maximum spring stroke and maximum force. The load deflection curve can be designed as linear, regressive or progressive, depending on the client's requirements.

RESTON®SDD are fabricated using highquality materials such as 51CrV4 (1.8159) with shot-blasted surface according to DIN 2098 to ensure excellent durability. Consequently, the dampers can facilitate up to 2 million load changes.

Testing

mageba RESTON®SDD and their disc springs conform to DIN 2098, and have also been tested independently by EMPA (Swiss Federal Institute for Material Testing) for their load capacity and spring stiffness. This testing confirms the characteristics and the durability of the product.

Quality

For five decades, mageba products have proven their worth in thousands of structures under the most demanding conditions. In addition to the product properties, the extensive experience of mageba's well-qualified manufacturing and installation staff also contributes to the high quality and durability of the products. mageba has a process-orientated quality system that is certified in accordance with ISO 9001:2008. mageba's factories are certified for welding in accordance with ISO 3834-2, and according to the current steel construction standard EN 1090.

Customer support

Our product specialists will be pleased to advise you in the selection of the optimal solution for your project, and to provide you with a quotation.

On our website, www.mageba.ch, you can find further product information, including reference lists and tender documentation.

References

Relevant Websites

- About this

data sheet - Product-ID

7468 - Published on:

16/02/2017 - Last updated on:

17/11/2021

mageba group

mageba group