New General Approval: Guide Bearings with MSM®

In 2003, the sliding material MSM® was patented and approved for the usage in spherical bearings inclusive of their guides. Due to its excellent material characteristics, it made inroads in the market, and is now well established. Deciding parameters as compared to PTFE are the double permissible stress, 5-fold accumulated sliding path, 7.5 fold sliding displacement, and the enhanced temperature range. In obtaining the German approval AbZ Z-16.9-463, these superior characteristics can now be employed in all guide bearings. The visible Ü-mark proves the high technical and quality level.

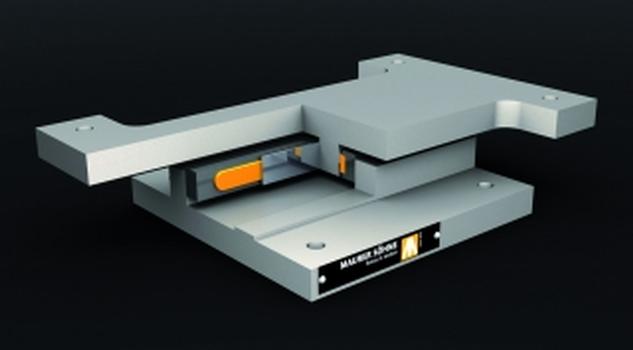

The new approval AbZ Z-16.9-463 addresses the guide bearings which are regulated by EN1337-8, in replacing PTFE with the sliding material MSM®. This results in advantages in terms of life time, flexibility, and economics.

5-fold life time increases economics

According to the new general approval, MSM® in guide bearings enjoys a life time of at least 50 years, which is a 5-fold increase in respect to the 10 years life time which is assumed for PTFE guides. Thus, MSM® results in savings in terms of (not required) replacement of bridge bearings during the course of the general life time of bridges. Corrosion protection set aside, MSM® bearings are maintenance free.

Moreover, the new general approval contains an exact mode of calculation of the life time. This way, fundamental statements can be made for the budget planning of the bridge structure over its total life time. Inclusive of a precast, whether and when guide bearings shall be replaced.

Double contact pressure

Compared to PTFE, MSM® can accommodate double contact pressure. For this reason, MSM® guide bearings can be designed more compact, which in turn greatly reduces the tilting moments. The compressive strength of MSM® can be compared with the CM1 which is regulated in EN1337-2. However, the incompressible CM1 reacts very sensibly to high edge pressures, which poses no problems for MSM®. Furthermore, CM1 cannot accommodate rotations - MSM® very well can.

In addition, the strain onto the adjacent structure is kept lower with MSM®, which is caused by the lower friction which is up to 65 % lower as compared to CM1.

Extremly wide temperature range

MSM® can be used at -50° to +70° C and so can be employed in all climatic zones world-wide, from Siberia to the Equator. PTFE is limited from -35° to +48° C.

Fixation elements at elastomeric bearings

A special topic in Germany are the guides of elastomeric bearings. Usually, CM1 is employed, which can be fixed economically, however due to its incompressibility only permits rotations around one main axis. Because at a structure also smaller rotations around the other 2 main axes occur, incompatible edge pressures would occur in CM1, which should have to be avoided by way of expensive constructive design measures. MSM® guide bearings spare this effort.

Structure Types

- About this

data sheet - Product-ID

3487 - Published on:

30/04/2012 - Last updated on:

19/05/2017

MAURER SE

MAURER SE