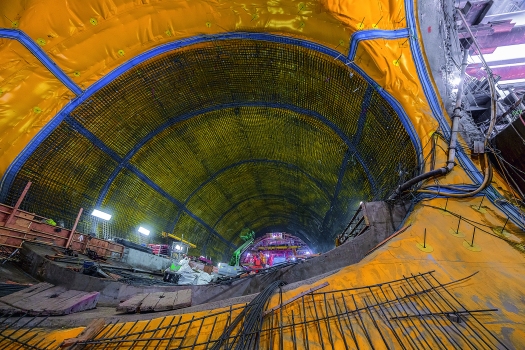

Chinatown Station deep in the heart of San Francisco

With construction work being carried out in depths up to 30 m in the centre of San Francisco, an enormous building structure is being realised. When completed, Chinatown Subway Station will form the northern end of the Central Subway System. The new station will significantly improve access to public transport in some of the city's most densely populated areas. The architectural requirements presented the contractor with enormous challenges.

Media

The highest point of the oval-shaped underground structure is still 17 m below Stockton Street which is why the construction using the cut-and cover method would have been too cumbersome and expensive. The contractor therefore decided in favour of shotcrete construction, also known as the New Austrian Tunnelling Method, in which excavation work takes place step-by-step from top to bottom. As more and more soft ground is excavated, temporary reinforcement provides support for the ever-increasing wall surface of the hollow space. Shotcrete applied to the surfaces supported the cavity until the inner lining could be cast in situ.

60 m long Chinatown Station with 15 m diameter

The solution provided by PERI engineers for executing the enormous 60 m long Chinatown Station with a 15 m diameter stipulated concreting operations in 9 m sections. In order to be able to carry the large and heavy formwork ring, a project-specific formwork carriage was realised. The pre-assembled formwork elements, comprised of formwork girders and plywood formliners, also saved weight when compared to using steel formwork.

The formwork elements were lowered from Stockton Street through the site access to a depth of 30 m and then mounted on the rail-guided tunnel formwork carriage. The hydraulic support accelerated shuttering operations after the reinforcement had been placed in position. Concreting took place alternately on both sides in order to keep the supporting structure balanced. Vibrators mounted on the formwork could also be activated as required which ensured uniform compaction of the poured concrete.

Different cross-section – same supporting structure

Once the procedure had been established, the 9 m sections could then be concreted in five to six hours thanks to the high permissible fresh concrete pressure of up to 90 kN/m². After each concreting operation, striking was easily and quickly carried out by means of the hydraulic support. The tunnel formwork carriage was subsequently pulled along rails using heavy-duty wheels to the next section.

After the first ten concreting cycles, the tunnel profile changed. Due to the flexible modular construction system complete with numerous rentable system components and a telescopic prop, the supporting structure together with the other components were easily adapted in order to accommodate the new geometry. Once equipped with the new formwork elements, the final 10 sections could likewise be quickly realised thanks to the well-coordinated and practised procedures.

References

Structure Types

- About this

data sheet - Product-ID

7641 - Published on:

12/06/2019 - Last updated on:

12/06/2019