Cable dampers for the World's Longest Stay Cables

A new standard is presently being set in China; the world's largest cable stayed bridge will receive stay cables of a length of up to 541 m. For the damping of the vibrations of these stay cables, innovative magneto-rheological dampers will be employed. This technology, which was co-developed by Maurer Söhne, was the deciding factor that Maurer was awarded the reputed contract for the supply and delivery of the cable dampers for this bridge. In addition, MAURER will supply the expansion joints, which count among the largest ever made, accommodating service movements of up to 2.60 m.

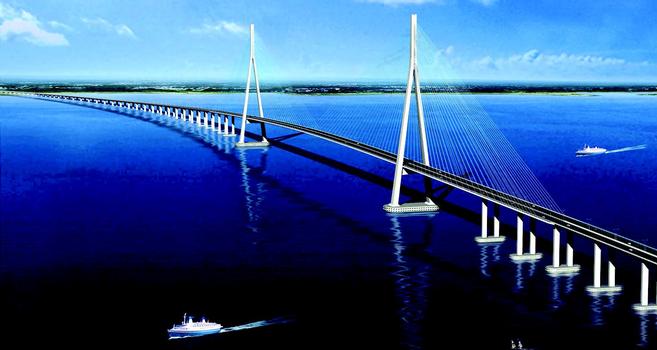

Not far away from Shanghai, the world's largest cable stayed bridge is presently under construction. The Sutong Bridge is scheduled to be opened end of 2008. In crossing the Yangtze River as a 6 lane road bridge, it will link the 2 cities Suzhou and Nantong. Main span is 1,088 m, and 2 pylons of a height of 306 m will accommodate a total of 272 stay cables of a length of up to 541 m. At the hand of the enormous length of the stay cables, it is apparent that considerable vibrations can occur. The trigger for the vibrations is not traffic, but wind, or a combination of rain and wind.

Preliminarily 200 cable dampers will damp these vibrations. They prevent a too strong vibration of the stay cables, consequently also vibrations of the bridge deck, and so they add to the service life of the stay cables. Further they facilitate the bridge to be kept open even in case of strong winds.

The deciding factor for the efficiency of the cable dampers is whether their response force is optimally tuned to the occurring vibrations. If the response force is too small, their damping efficiency is reduced, and if the response force is too strong, they "clamp" the cable and thus, then acting as a fix point, reduce the vibrating length of the stay cable, which will continue to vibrate undamped, but only in a shorter length. Further, depending on the mode of the vibration, different response forces of the damper may be required to optimally damp the cable. The solution to these problems is found in so called adaptive magneto-rheological dampers, which enables the damper to adapt its response force automatically within milliseconds to the required optimum response force. This technology was co-developed by Maurer Söhne in the frame of a Research Project called SPACE which was sponsored by the European Union.

Electronics control the response force

In the Sutong Bridge, the longest 48 stay cables will be damped with this innovative technology.

The core of the adaptive dampers lies in an electronics system which measures the actual vibrations of the cable and then computes the required response force. The hydraulic dampers consist quite conventionally of a cylinder, a piston, and a fluid. The fluid however is magnetic, and its shear strength, that is its viscosity, can be controlled by a surrounding magnetic field. Already by controlling the current that creates the magnetic field, the resistance can be controlled with which the damper reacts to the respective vibration. The 48 dampers are semiactive, which means that they do not actively introduce a force, but just vary their resistance.

Another 152 cables will be equipped with linear-viscous passive dampers. These dampers are preset to a certain response force that is an compromise for the total system, but not an optimum for each individual mode. They do not control themselves, but entail a constant viscosity. It cannot be ruled out that eventually the remaining 72 shortest stay cables will be equipped with cable dampers.

The world's largest modular expansion joint

At the hand of the innovative self-controlling dampers, in the expert world it can be considered almost as routine that the expansion joints for the world's biggest cable stayed bridge also will be supplied by Maurer Söhne. The company which is located in Munich is rated as world market leader in this field. These expansion joints already entail big dimensions when in transport: each of the 4 halves is 17 m long, about 5 m wide, and weighs 50 t. The delivery will be carried out by boat service, and the installation is planned for summer 2007.

Installed in the bridge, these expansion joints have a classical task to accomplish: they have to accommodate movements caused by traffic, wind, or earth quake. The swivel joist joints of type DS2600 can accommodate movements of ± 1,30 m, thus in total 2,60 m.

References

Structure Types

- About this

data sheet - Product-ID

6180 - Published on:

18/03/2013 - Last updated on:

19/05/2017

MAURER SE

MAURER SE