General Information

| Other name(s): | Waschmühltalbrücke |

|---|---|

| Beginning of works: | January 2011 |

| Completion: | 30 August 2013 |

| Status: | in use |

Project Type

| Structure: |

Four-span extradosed bridge |

|---|---|

| Function / usage: |

Motorway bridge / freeway bridge |

| Material: |

Steel-reinforced concrete composite bridge |

Awards and Distinctions

| 2015 |

Honorable Mention

for registered users entry for registered users |

|---|

Location

| Location: |

Kaiserslautern, Rhineland-Palatinate, Germany |

|---|---|

| Part of: | |

| Next to: |

Waschmühl Viaduct (1937)

|

| Coordinates: | 49° 27' 24.88" N 7° 45' 39.30" E |

Technical Information

Dimensions

| total length | 226.50 m | |

| span lengths | 45.40 m - 2 x 68.10 m - 44.90 m | |

| deck width | 18.10 m | |

| number of spans | 4 | |

| bridge surface | 4 134.05 m² | |

| piles | diameter | 1.20 m |

Quantities

| parapets | concrete volume | 285 m³ |

| reinforcing steel | 35 t | |

| piles | total length of piles | 221 m |

| substructure | concrete volume | 2 200 m³ |

| reinforcing steel | 515 t | |

| superstructure | structural steel | 1 700 t |

| concrete volume | 1 500 m³ | |

| reinforcing steel | 596 t |

Design Loads

| live load | LM 1 | |

| design code(s) | DIN FB 101 |

Cost

| cost of construction | Euro 13 600 000 |

Materials

| deck slab |

reinforced concrete

|

|---|---|

| girders |

steel

|

New construction of the Waschmühltal Bridge, Kaiserslautern — Harmonious Symbiosis between an Architectural Monument and a new Structure

Task

In the course of the six-lane expansion of the A6 Mannheim-Saarbrücken motorway, the Waschmühltal bridge, which is a listed building, had to be repaired and widened. This involved erecting a new structure next to the historic sandstone arch bridge.

The Waschmühltal Bridge, which was built with the assistance of architect Paul Bonatz between 1935 and 1937, is considered a successful synthesis of engineering achievement, architecture and landscape design and was added to the list of historical monuments in 1984.

Due to the special situation and design significance of the highway bridge designed by Paul Bonatz, an invitational competition was held. About the winning design – a spanned continuous girder – judged the jury as follows:

„The design clearly sets itself apart in form and construction from the existing historic arch bridge. At the same time, however, it picks up on the structure of the existing structure and emphasizes its rhythm and design. The low number of supports and the slender superstructure due to the span allow a largely unobstructed view of the existing structure. On the one hand, the adaptation to the existing structure has been achieved in an outstanding manner; on the other hand, the new structure represents an independent striking construction in a modern design.“

Description of the construction and choice of building materials

The focus of the design process leading to this result was to address the existing Waschmühltal Bridge from the primary perspective of dealing appropriately with the existing structure and respecting the quality and design of Paul Bonatz's bridge. The overall objective was to create an engineering structure with its own identity, which would both blend into the landscape and form a fitting counterpart to the architectural monument „Waschmühltal“. The following design and construction principles were used as a basis:

- Semi-integral construction:

- Omission of bearings (except for abutment areas)

- bending-resistant connection between the reinforced concrete columns and the steel (composite) superstructure

- thereby in longitudinal and transverse direction bending stiff frame systems which allow extremely slender column formations (reduction of buckling length)

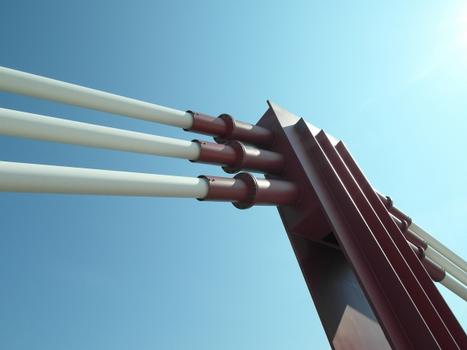

- Spanned continuous beam:

- Static system of haunched continuous beam over four spans (44.90 m – 68.10 m – 68.10 m – 45.55 m)

- Resolution of the haunch by means of steel masts and steel tension members as spans

- Cassette-shaped superstructure:

- Two stiffening girders as tightly welded hollow boxes and cross girders at a distance of 3.25 m

- 35 cm thick in-situ concrete carriageway slab

- Composite action only in the transverse direction

- Material implementation and joining.

- Highly stressed tension members (overstressing) as high-strength parallel strand bundles

- Girder grid made of structural steel-welded

- Realization bending resistant frame corner via steel fixtures with shear stud and concrete dowel

- Readability

- Pole with stiffeners laid outward – transparency and see-through

- Material separation between columns (concrete) and superstructure longitudinal beam (steel) – Functionality of the continuous beam becomes clear

- Flat inclination of „cables“ – demarcation of the spanned girder to the structure type of cable-stayed bridge

- Parallel strand bundle with fixed anchors at the top of the mast and tension anchors at the bottom of the superstructure (visible) - sense of suspension

- Bridge soffit mainly characterized by girder grating – architecturally elegant effect

- Pillars in view with downward tightening – analogous to piers of arch bridge

The production took place conventionally as a crane assembly. After fabrication of the deck, the strand tendons were pulled in and tensioned to the required prestressing force (adjustment of the system via force-controlled fabrication).

Special engineering achievement

In times of dwindling resources, questions regarding the sustainability of structures are becoming increasingly important. The carriageway slab only acts in the transverse direction in the composite and can therefore be replaced without additional measures and risks. Later reinforcement of the structural steelwork by means of lugs is possible without any problems. The guy cables were designed with larger anchors so that additional strands could be installed if necessary. In the area of the flexurally stiff frame corners, there is also potential for strengthening by means of a concrete anchor approach that can be implemented in due course. However, the decisive factor in ensuring the longevity of the bridge remains the bearingless design. Integral bridges are characterized by a high degree of robustness (durability, maintenance, structural safety, redundancy) and also open up new possibilities in terms of design and layout.

In summary, it can be stated that with the new construction of the Waschmühltal Bridge, a design solution was realized that sought an engagement with the existing architectural monument at „eye level“.

The harmonious symbiosis was not achieved by way of subordination, but rather in the sense of a common inner attitude committed to the building culture. For all the contrasts in design and structural form, the result is a high degree of complementary unison.

The new bridge forms a clear and convincing counterpart to the existing structure, which is evident in many ways:

- The new bridge has been broken up into a bar shape, giving it a light and delicate appearance. It thus corresponds to the design principle of the Waschmühltal Bridge by Paul Bonatz, who had created a light and filigree construction for an arch bridge.

- A compression-loaded arch, whose supporting structure is located under the roadway, is opposed by a tension-loaded structure, whose supporting structure was placed above the roadway.

- Different materials were also chosen in accordance with the different load-bearing principles. At the time, the compression-loaded structure was made using stamped concrete and sandstones, while the tension-loaded structure uses high-strength tension members.

- The existing Waschmühltal bridge is a structure that blends into the landscape, but also clearly occupies it. The new bridge represents a clear contrast in that it deliberately keeps the valley free.

Explanatory report of Leonhardt, Andrä und Partner Beratende Ingenieure VBI AG for submission to the Ulrich Finsterwalder Ingenieurbaupreis 2015.

Participants

-

Ruhrberg Ingenieurgemeinschaft

- Winfried Neumann (checking engineer)

Relevant Web Sites

There currently are no relevant websites listed.

Relevant Publications

- (2009): »Ergänzung« der Waschmühltalbrücke. Symbiose aus Denkmal und Neubau. In: Brückenbau, v. 1, n. 4-1 ( 2009- 2010), pp. 20.

- (2014): Innovation neben Tradition - Neubau der Waschmühltalbrücke Kaiserslautern. In: (2014): Ingenieurbaukunst 2015. Ernst & Sohn, Berlin (Germany), ISBN 9783433030967, pp. 112-119.

- (2010): Neubau der Waschmühltalbrücke - Harmonische Symbiose Baudenkmal-Neubau. In: Stahlbau, v. 79, n. 5 (May 2010), pp. 370-388.

- (2013): Neubau der Waschmühltalbrücke im Zuge der A 6 bei Kaiserslautern, ein nicht alltägliches Bauwerk. Presented at: 23. Dresdner Brückenbausymposium, Dresden, 12. März 2013.

- About this

data sheet - Structure-ID

20043400 - Published on:

04/02/2009 - Last updated on:

26/05/2020