Corrugated steel components for civil engineering

The corrugated steel construction method, which appeared for the first time in the USA around 100 years ago, was introduced into the German market by Hamco in 1956. Since then this construction method has been always significantly supported by Hamco through scientific studies and technical tests. Prefabricated corrugated steel elements are used today for civil engineering, road construction, industry and agriculture.

Media

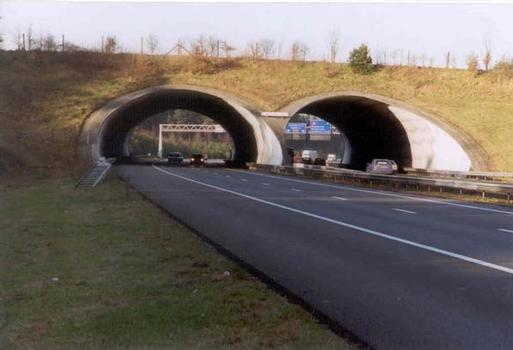

One of the results of the scientific investigations and technical testing is the Klöppel/Glock design method which, even today, is still anchored in many guidelines for the design of corrugated steel pipes. Beside the traditional applications such as culverts, pedestrian underpasses, conveyor belt tunnels and silos for industry and agriculture, Hamco corrugated steel pipes have often been used for sensational projects, e.g. the mountain railway station at the Zugspitze (altitude 2600 m) or the Germany’s two research stations in Antarctica. Hamco prefabricated steel parts have always been used for connecting the natural habitats of wild animals by means of crossings above or below busy roads. Besides the several crossings made from prefabricated steel parts, the "Greenbridge” made of Hamco MultiPlate over a section of road in the Dutch national park "Woeste Hoeve” between Arnhem and Apeldoorn is still one of the most impressive structures worldwide ever constructed using the corrugated steel pipe product MP 200.

Most recently, Hamco has extended its sales programme by adding a further corrugated steel product which permits much larger spans and profiles to be realized with an remarkable rise-to-width ratio. Irrespective of the corrugated steel product, the construction method is characterized by:

- A wide spectrum of profile shapes and profile dimensions

- Fast and simple assembly of the prefabricated steel parts (short construction times)

- Immediate loading of the corrugated steel pipe after correct assembly and backfilling

- A long service life thanks to first-class corrosion protection

- Low planning and construction costs

- Very low, often zero, maintenance costs

- About this

data sheet - Product-ID

6283 - Published on:

22/05/2013 - Last updated on:

03/03/2020