Solutions for an avoidable problem: Corrosion protection at expansion joints

It is an embarrassing problem, and it costs money: damages at the corrosion protection of expansion joints, which are already visible before the bridge is opened to the traffic. Maurer Söhne presents two solutions for avoidance: stainless steel or edge profile protection. "We have several years of experience with this issue. It is now upon the owners of the bridge or the concessionaries to request such a possible quality”, explains Rolf Kiy, who is responsible for the work group "Corrosion Protection” at Maurer Söhne.

Media

In Germany, the combined length of all expansion joints is about 5,000 km. The procurement costs make about 1 % of the total costs of a bridge. In the course of a maintenance check of over 2,000 bridges in the state of Bavaria, the owner which is the Southern Bavarian Expressway Administration noticed that less than 5 % of all damages fall into the category of bridge bearings and expansion joints. However, the major share of these damages is located in the upper part of the expansion joints. Experts detected several main reasons for such damages at the corrosion protection:

- Unprotected passing of the expansion joints in construction phase or during the renovation of asphalt.

- Corrosion protection being damaged during the reinforcement of the footway section by way of reinforcement bars.

- Damage caused by the cut of the bituminous filler after concreting and asphalting

- Dirt that has a paint erasing effect.

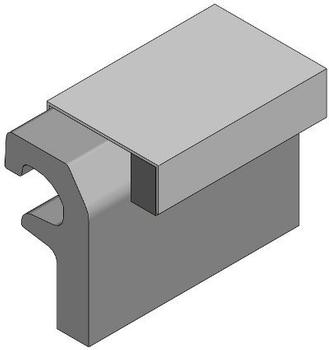

- Hybrid profile with stainless steel head.

- Maurer edge profile protection at the concreting phase of the footway section, which is connected with an on site created protection during construction phase.

Hybrid: Upper part in stainless steel

The principle of the hybrid profile is a simple one: the upper part of the profile is being made of stainless steel, which employs a long term resistance against corrosion. The hybrid structure of the edge beam is being employed in order that the lower part of the profile which consists of mild steel can ensure an optimum welding connection with the anchorage in the bridge structure.

Of course this welding seam has been structurally analysed and is fatigue tested as well as enjoys the General Approval. The electrolyte is being kept away with a side cover in order to prevent crack corrosion. Moreover the hybrid profile can be provided with upper rhombic plates for the purpose of reduction of noise emission.

Already passed the real life test

The first hybrid joints were installed in 2006 at the region of Ansbach and thereafter very thoroughly examined. After more than 5 years in service the expansion joints look like new. Thus we can say that this solution is a proven one.

Install safely against corrosion

The second approach in terms of corrosion protection aims at the situation during installation. Generally it should be observed that the expansion joint shall be protected during installation, in particular when it comes to passings of job site vehicles.

Along the edge of each expansion joint there is a bituminous filler, which is a gap that must be kept free when the expansion joint gets an asphalt connection or a concrete connection at the footways, or it must be cut free ex post. However a later free cutting will almost always damage the corrosion protection of the edge beams.

Edge profile protection keeps the joint at the footway area free

Maurer Söhne offers a solution for this problem: the edge profile protection. It consists of a special plastic cap which is being clamped onto the edge beams of the expansion joints. Like a formwork it keeps the space of the bituminous filler in the specified thickness. After the concreting this protection layer is being removed. The bituminous filler is free, and the corrosion protection remains undamaged.

We would like to mention here that the responsibility of the protection of the corrosion of the expansion joint during the construction phase is with the contractor, which must be made clear and ensured by the supervisor. Usually, the required protection covers during construction phase consist of a plastic foil and/or of wood.

- About this

data sheet - Product-ID

6111 - Published on:

17/12/2012 - Last updated on:

11/12/2014

MAURER SE

MAURER SE