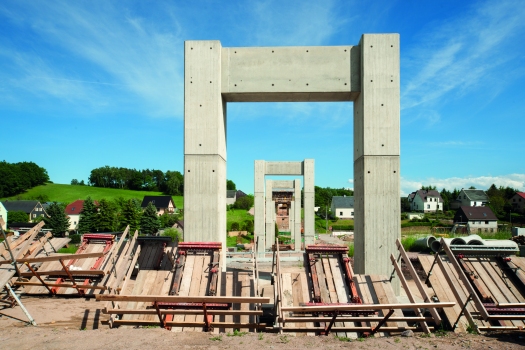

Slender columns for the steel girder bridge near Kirchberg, Germany

The residents of the "Seven-Hill Town" of Kirchberg near Zwickau can look forward to being relieved of the daily traffic rolling through their delightful town with the completion of a bypass. A steel girder bridge is currently being built to the southwest of Kirchberg as part of the works. The bridge superstructure rests on 18 columns. The columns are so slender that an extremely flexible and yet robust formwork system was required to construct them: NOEratio manufactured by NOE-Schaltechnik, Süssen in southern Germany.

Media

The Saxony State Directorate approved the construction of the S 282 n Kirchberg Bypass in 2012. The aim of the project was to improve the traffic situation in the small Saxon town and build a link to the federal road B93, one of the region's most important north-south routes. One of the structures required in order to complete the project was a bridge over the Leutersbach valley. This 254 m long structure was designed as a steel girder bridge supported on 18 columns in 9 piers, each pier consisting of a pair of columns. Each pair of columns is connected at the top and shares a common foundation. Each of the pairs of columns has the same rectangular cross section but is of different height to suit the topography. The tallest pair is just short of 16 m high.

Column positions

The most noticeable feature of the columns is their small cross section of only 1.10 x 1.40 m. This gives the substructure a very slender appearance. The small cross sections and the short distance of only 4.26 m between the columns presented a special challenge to the formwork team on site. As a consequence, the available space, for example to attach the climbing scaffold and to integrate the screw anchors, was extremely tight. The beam that joins each pair of columns across their tops also had to be cast together with the columns in one pour. As a result of the confined space, the bottom form of the beam had to be light enough to be handled manually. In order to fulfil these requirements efficiently, the main contractor, Arlt Bauunternehmen GmbH from Frankenhain, decided to use NOEratio from NOE-Schaltechnik. This is an extremely flexible beam formwork system specially designed for engineering and system-built structures. It consists of three main elements: steel bracing, NOE H 20 timber beams and NOEform facing. Engineers based in NOE's Cottbus office design the formwork for each project individually to ensure it can be used as efficiently as possible.

NOEratio

The formwork elements are assembled in the factory at NOE Cottbus so that the formwork arrives on site ready for use. NOE-Schaltechnik offers an extensive range of accessories for the NOEratio system, such as climbing brackets and working scaffolds. These also eased the task of the contractor in constructing the steel girder bridge.

Thanks to the panel grid width being only a very helpful 25 cm, the site team installed the formwork without any problems, even with the tight gap between the columns.

Despite the narrow panel width, NOEratio is capable of forming large areas in a single pour because the system allows forms of up to 36 m² in area to be moved in one piece. In general, the panels are tied with 15 mm diameter tie rods. The formwork is torsionally very stiff, which allows a relatively free choice of tie rod positions. The only other aspect to take into account is the allowable concrete pressure of 50 kN/m² for a maximum tie rod spacing of 120 cm. With tie rods spaced at a maximum of 100 cm, the allowable concrete pressure rises to 60 kN/m².

Special solutions

This flexibility also proved beneficial to contractor Arlt on the bridge over the Leutersbach valley: originally, the contractor intended to use four tie rods over a form height of 5 m. In order to work more efficiently and achieve a better final appearance, the site manager proposed using as few tie rods as possible on this structure. The NOE engineers at the Cottbus office were able to satisfy this wish with NOEratio and reduce the number of tie rod positions to only two – one in the top and another in the bottom part of the formwork element. Moreover, they offset the tie rods in height by 10 cm to ensure they did not intersect one another. The rate of pour had to be slightly reduced to compensate. The overall effect was to make the work on site much simpler and quicker.

The finished job not only looked good but was also economically efficient. The columns were absolutely flawless in shape and quality of surface finish, and the use of NOEratio proved highly economical compared to the alternative of expensive special formwork, which would have required more time to fabricate. In conclusion, the project partners can only be congratulated on their planning and execution of the works.

References

Structure Types

- About this

data sheet - Product-ID

7287 - Published on:

23/10/2015 - Last updated on:

28/01/2016